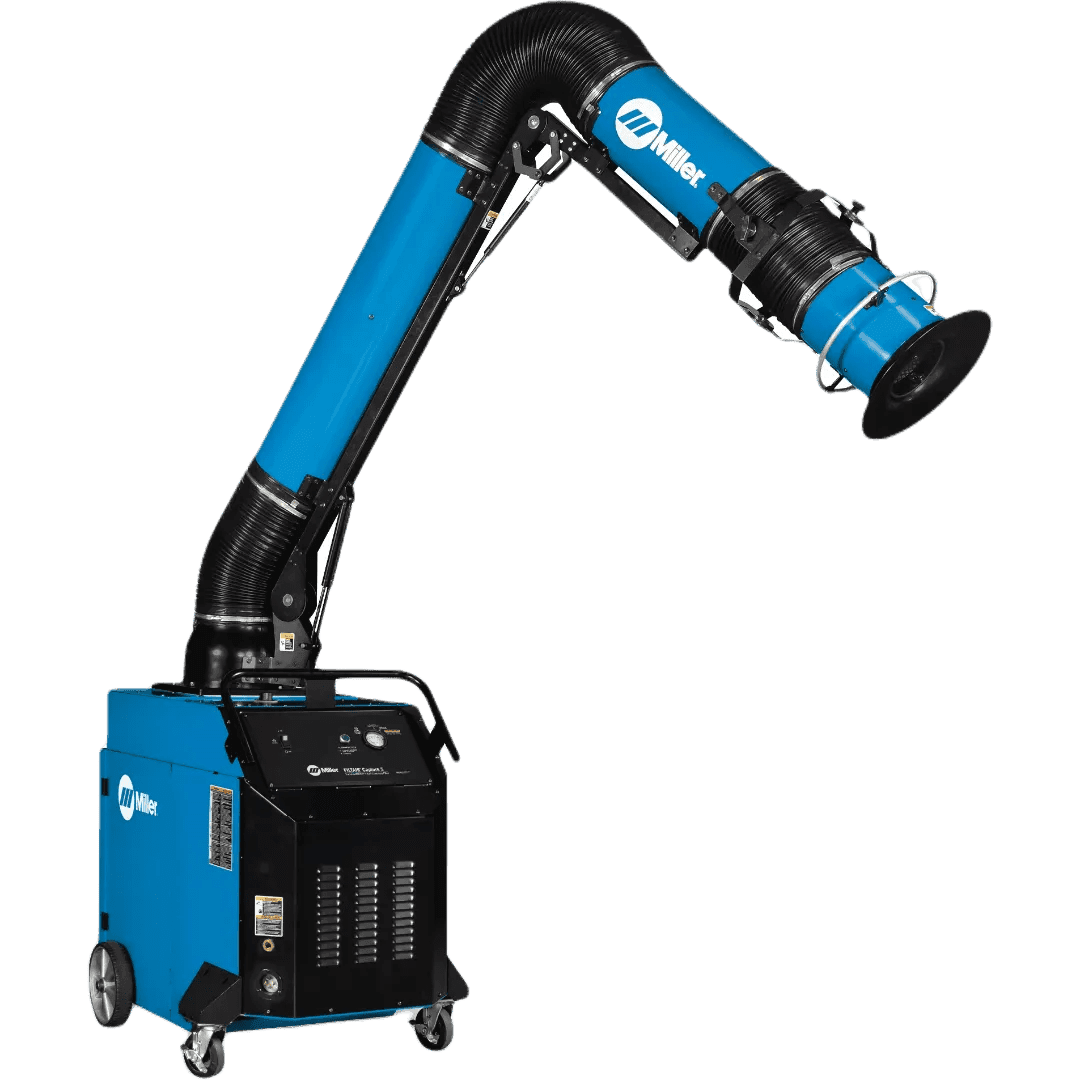

Welding fume extractors are essential for providing clean air in welding environments, where harmful fumes and gases can pose serious health risks. These extractors use filtration systems to capture and remove hazardous particles, gases, and vapors produced during welding. They are equipped with powerful fans and multiple filtration stages to ensure that the air remains free of contaminants. These extractors help to create a safer, healthier workplace and comply with international standards like ISO 15012 and SASO 2350 for welding fume control. Welding fume extractors come in various sizes and configurations, including portable models for smaller workspaces and larger systems for industrial settings.

Key Features:

- Effective Fume Removal: Equipped with multiple filters to remove harmful particles and gases.

- Portable or Stationary Options: Available in both mobile and fixed configurations.

- Easy Maintenance: Designed for quick filter changes and minimal maintenance.

- Quiet Operation: Many models are designed to operate quietly, minimizing workplace noise.

Types and Standards:

- Portable Welding Fume Extractor: Ideal for smaller workspaces or mobile applications.

- Stationary Welding Fume Extractor: Larger units designed for use in industrial or workshop environments.

- **ISO 15012, SASO 2350: Standards ensuring proper filtration and air quality control.

Brands Available:

Lincoln Electric, Miller Welds, ESAB, Kemper, and Donaldson are known for producing high-quality welding fume extractors.

General Maintenance:

Regularly replace filters and check for blockages in the ventilation system. Inspect the fan motor for wear and clean the unit to ensure optimal performance. Ensure the extractor is properly maintained to maintain air quality standards.