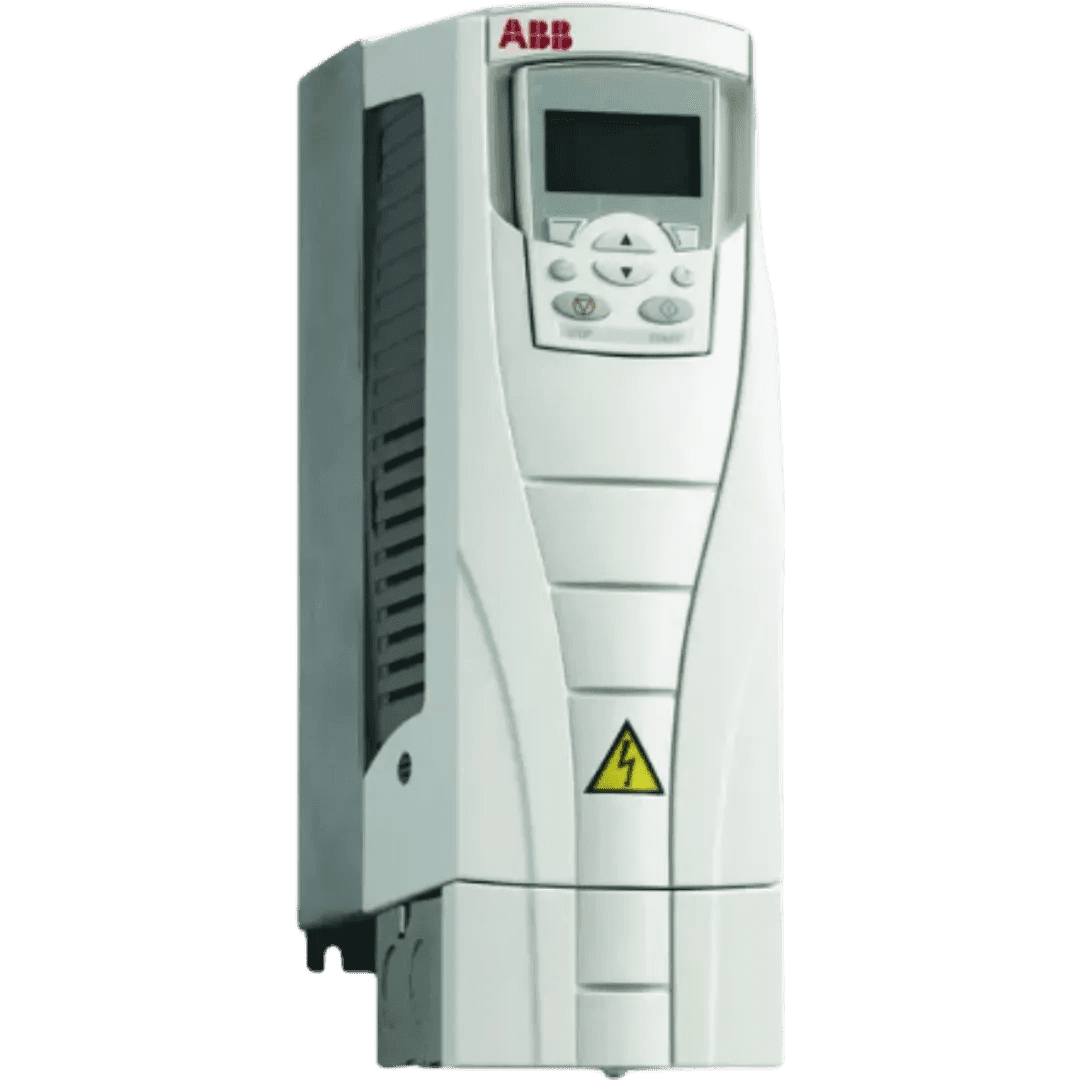

Variable Frequency Drives (VFDs) are devices that control the speed of electric motors by adjusting the frequency and voltage of the electrical supply. VFDs are used in applications where motor speed needs to be adjusted according to load conditions, such as in HVAC systems, water pumps, compressors, and conveyor systems. By controlling the motor speed, VFDs help to reduce energy consumption, lower operational costs, and extend the lifespan of equipment. VFDs also provide smooth acceleration and deceleration, preventing mechanical shock. They are available in both low and high voltage models, with digital interfaces for monitoring and adjustments.

Key Features:

- Energy Efficiency: Reduces power consumption by adjusting motor speed according to demand.

- Speed Control: Provides precise motor speed control to optimize processes.

- Smooth Start/Stop: Prevents motor damage due to mechanical stress by ensuring smooth acceleration and deceleration.

- Compact and Versatile: Available in various sizes and models for different motor capacities.

Types and Standards:

- Low Voltage VFDs: Common for applications with motors up to 600V.

- High Voltage VFDs: Suitable for motors operating above 600V.

- Standard VFDs: For general industrial applications.

- **IEC 61800-5-1: Safety and performance standards for VFDs in industrial applications.

Brands Available:

Siemens, Schneider Electric, ABB, Yaskawa, Rockwell Automation.

General Maintenance:

Check VFD parameters regularly and ensure proper calibration. Clean air filters and cooling fans to prevent overheating. Monitor motor connections and the drive’s cooling system for optimal performance.