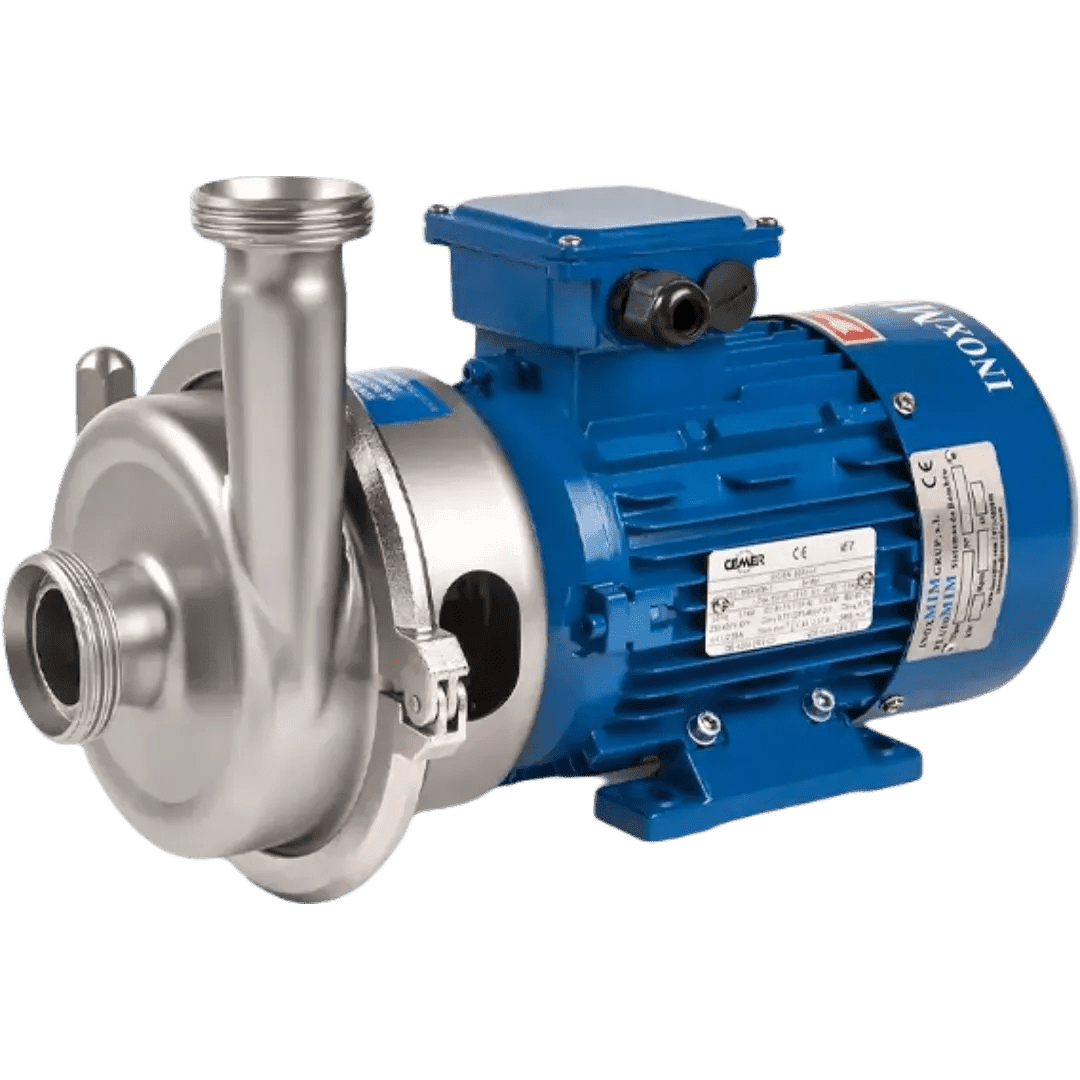

Industrial pumps are critical for the transportation of liquids and slurries across various industries such as oil & gas, chemicals, pharmaceuticals, and water treatment. These pumps come in different designs based on the type of fluid being pumped, including centrifugal pumps for high-flow applications, diaphragm pumps for transferring corrosive or viscous materials, and peristaltic pumps for accurate dosing of chemicals. Each type of pump is designed to handle specific pressures, flows, and viscosities. Regular maintenance, including checking seals, bearings, and valve operation, is essential to ensure continuous, efficient operation.

Key Features:

- Versatile: Suitable for a wide range of liquids, including chemicals, slurries, and water.

- Variety of Types: Includes centrifugal, diaphragm, peristaltic, and gear pumps.

- Durable Materials: Designed to withstand harsh industrial environments.

- Energy-Efficient: Built to minimize energy consumption while maximizing performance.

Types and Standards:

- Centrifugal Pumps: Ideal for high-flow, low-viscosity liquids.

- Diaphragm Pumps: Used for corrosive or viscous fluids.

- Peristaltic Pumps: Accurate, pulse-free flow for dosing applications.

- **ISO 9001: Standard for manufacturing and performance.

Brands Available:

Graco, Grundfos, Wilden, Flowserve, Xylem.

General Maintenance:

Inspect seals and gaskets regularly for wear and replace as needed. Lubricate bearings and check pump impellers for damage. Perform routine flow and pressure checks to ensure optimal performance.