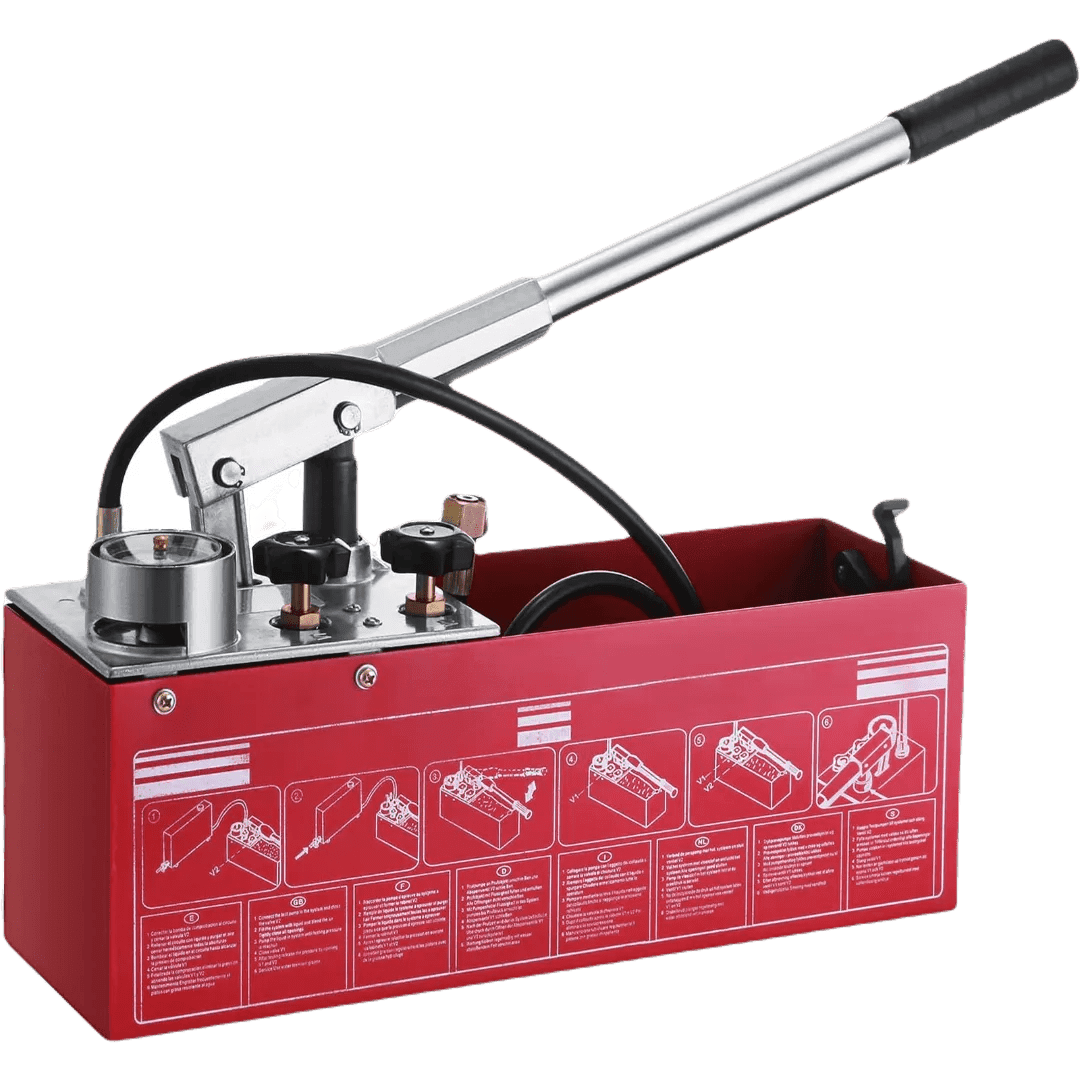

Hydraulic pressure test pumps are designed to provide precise pressure for testing the integrity of hydraulic systems, pipelines, valves, and other components. These pumps are crucial in industries where high-pressure testing is required to ensure safety and functionality. They are often used to verify the strength and leak-resistance of hydraulic lines and equipment. The pumps typically feature a high-pressure output, adjustable pressure settings, and a durable construction that can withstand harsh working conditions. They meet industry standards for safety and reliability and are available in manual, electric, and air-driven models.

Key Features:

- High-Pressure Testing: Designed to test hydraulic systems under pressure.

- Durable Construction: Built to handle harsh industrial environments.

- Adjustable Pressure: Easy to control and adjust pressure levels for various testing needs.

- Portable Options: Available in compact, mobile models for flexible testing.

Types and Standards:

- Manual Hydraulic Pressure Pumps: Operated by hand, ideal for smaller systems.

- Electric Hydraulic Pressure Pumps: Suitable for larger systems and continuous operation.

- Air-Driven Pumps: Powered by compressed air for mobile and rugged testing.

- **ISO 9001: Ensures reliability and performance in industrial applications.

Brands Available:

Enerpac, Rexroth, Hydratron, Atlas Copco, Hydraulic Systems Inc.

General Maintenance:

Regularly check seals and O-rings for wear. Inspect the pump for leaks and clean the pressure relief valves. Ensure the pressure gauge is calibrated and functioning correctly.