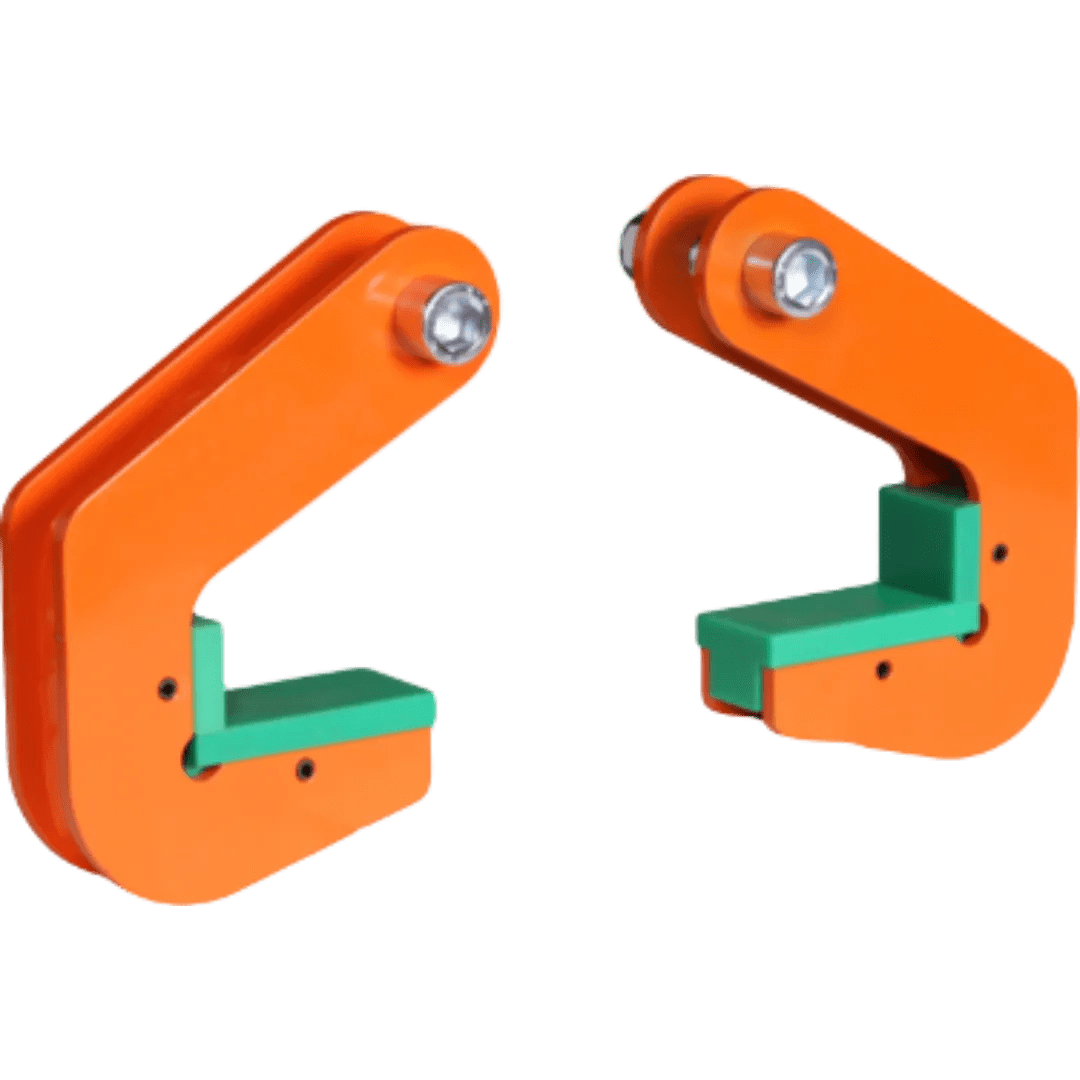

Horizontal pipe clamps are specifically designed to lift and transport pipes and cylindrical materials in horizontal positions. These clamps provide a secure and stable grip on pipes, ensuring they can be safely lifted and moved without risk of slippage or damage. They are commonly used in construction, pipefitting, and industrial applications where large pipes or tubes need to be lifted and placed accurately. Horizontal pipe clamps are typically made of high-strength steel and are equipped with safety features such as locking mechanisms to prevent accidental release. They meet safety standards like ASME B30.20 and SASO 1300 to ensure their strength and reliability.

Key Features:

- Safe Lifting: Provides secure lifting for horizontal pipes and cylindrical materials.

- High Strength: Made from durable steel to handle heavy loads.

- Adjustable Size: Many models feature an adjustable design to fit various pipe diameters.

- Safety Mechanisms: Equipped with locks or latches to ensure the load remains secure.

Types and Standards:

- Fixed Horizontal Pipe Clamps: Designed for specific pipe sizes.

- Adjustable Horizontal Pipe Clamps: Can be adjusted to fit different pipe diameters.

- **ASME B30.20, SASO 1300: Safety standards ensuring strength and reliability.

Brands Available:

Crosby, Kito, Lift-All, Harrington, and Peerless offer a wide range of horizontal pipe clamps for industrial lifting applications.

General Maintenance:

Regularly inspect the clamp for signs of wear, corrosion, or damage to the locking mechanism. Lubricate the moving parts to ensure smooth operation. Clean after use and store in a dry area to prevent rust and damage.