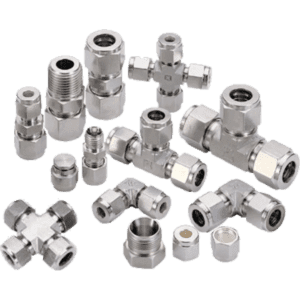

Flanges are mechanical components used to connect different sections of pipe or connect pipes to valves, pumps, or other equipment. They are usually bolted and sealed with gaskets to ensure a leak-proof joint. Flanges come in different types, such as weld neck, slip-on, blind, and threaded, each offering specific advantages for different applications. Flanges are commonly made of stainless steel, carbon steel, or alloys, depending on the fluid being transported and the system’s pressure and temperature conditions. Proper installation and regular inspection are essential to prevent leaks and ensure the integrity of the connection.

Key Features:

- Leak-Proof Connections: Used to securely connect pipes and equipment.

- Variety of Types: Includes weld neck, slip-on, blind, and threaded flanges.

- Durable Construction: Available in various materials like stainless steel and carbon steel.

- Standardized Designs: Complies with ANSI, DIN, and JIS standards for various industrial applications.

Types and Standards:

- Weld Neck Flanges: Provides a strong, reliable weld joint for high-pressure systems.

- Slip-On Flanges: Easy to install and ideal for low-pressure applications.

- Blind Flanges: Used to seal the end of a pipe.

- **ANSI B16.5, DIN 2573: Common standards for flange dimensions and pressure ratings.

Brands Available:

*Swagelok

*, Parker, Tyco, Alfa Laval, Tranter.

General Maintenance:

Inspect flanges for corrosion and signs of wear. Ensure that gaskets are properly seated and check for leaks during operation. Tighten bolts to the manufacturer’s torque specifications.