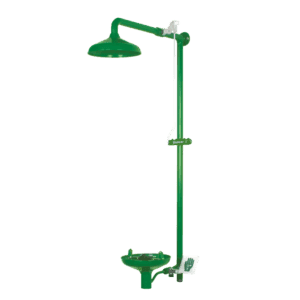

In environments where emergency eye wash stations are required, it’s essential to ensure that the water used is free of bacteria, contaminants, and other harmful agents. Bacteriostatic solutions are added to the water supply in eye wash stations to prevent the growth of microorganisms, ensuring the water remains safe for eye irrigation in case of emergencies. These solutions are especially important in areas where water may sit unused for extended periods, such as remote work sites or industrial locations. Typically made from gentle, non-irritating substances, bacteriostatic solutions maintain the effectiveness of the eye wash and meet safety standards like ANSI Z358.1 and SASO 2107.

Key Features:

- Prevents Bacterial Growth: Stops bacteria from growing in eye wash stations, maintaining safe water quality.

- Non-Irritating: Formulated to be gentle and non-harmful when used for emergency eye flushing.

- Long Shelf Life: Can be stored for long periods without losing effectiveness.

- Meets Standards: Complies with ANSI Z358.1 and SASO 2107 standards to ensure optimal performance.

Types and Standards:

- Eye Wash Station Additive: Added directly to the water in eyewash stations.

- Ready-to-Use Solutions: Pre-packaged and ready to be poured into eye wash stations.

- ANSI Z358.1, SASO 2107: Standards that govern the composition and use of eye wash water solutions.

Brands Available:

Haws, Guardian, Bradley, Speakman, and Misty provide high-quality bacteriostatic solutions that ensure safe and effective water for eye washing in emergency situations.

General Maintenance:

Regularly check the bacteriostatic solution to ensure it is within the recommended expiration date. Replace the solution in the eye wash station as required, particularly if there is a change in the water supply or if the station has not been used in a while. Clean the eye wash nozzles and test the flow regularly to ensure water flows effectively during an emergency.