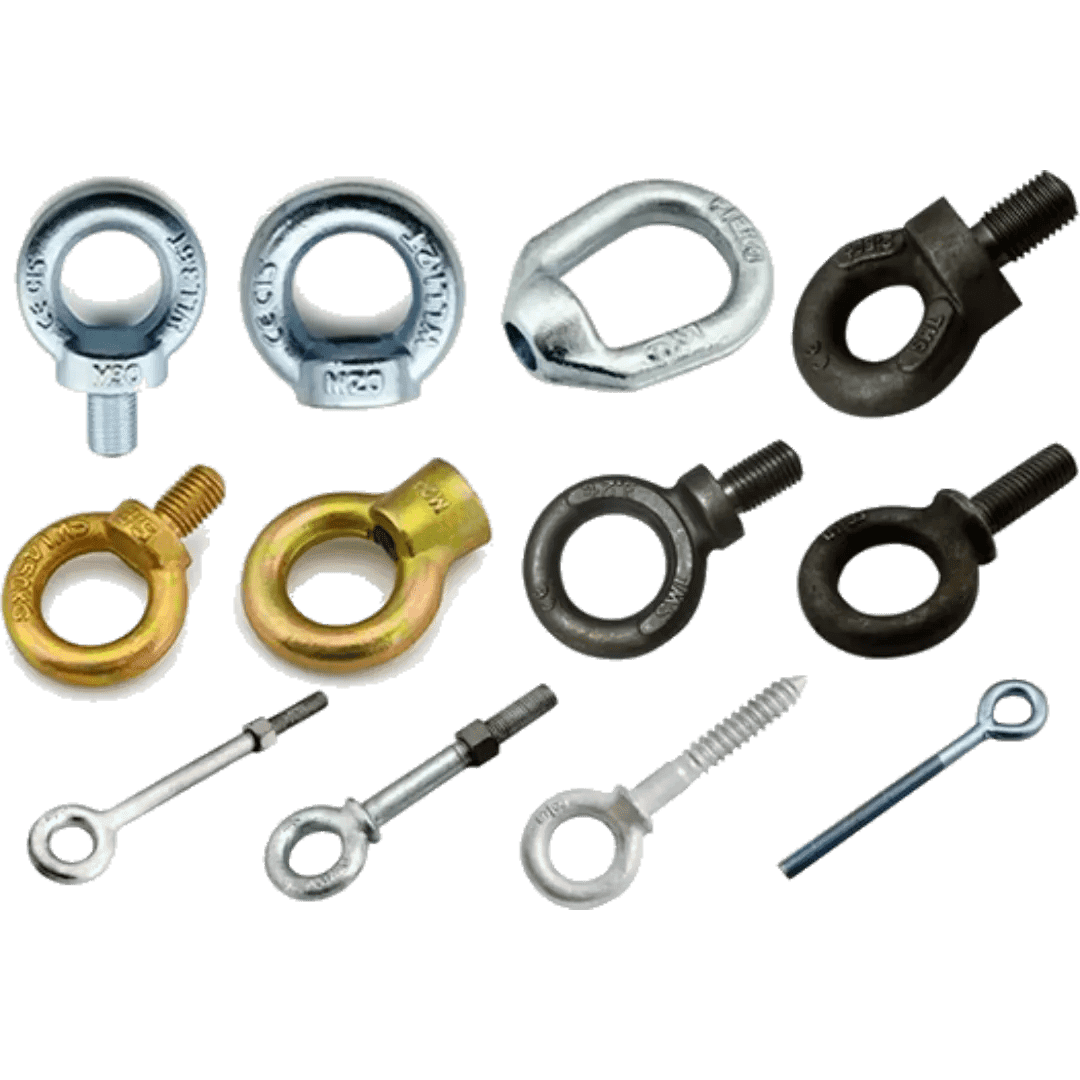

Eye bolts and nuts are crucial in lifting and securing loads, providing a safe attachment point for lifting slings or hooks. These bolts are available in various sizes and materials, with the most common being steel, stainless steel

, and alloy steel. Eye bolts are designed to be used in both vertical and angular lifting applications. They are typically used in construction, manufacturing, and marine industries, where secure lifting points are essential for safety. Eye bolts and nuts are manufactured to meet standards such as DIN 580 and SASO 2101, ensuring they can handle heavy loads reliably.

Key Features:

- High Load Capacity: Suitable for heavy lifting tasks.

- Multiple Designs: Available in different configurations, such as shoulder eye bolts and long shank eye bolts.

- Durable Construction: Made from high-strength steel, stainless steel, or alloy steel.

- Corrosion Resistance: Stainless steel options are available for use in corrosive environments.

Types and Standards:

- Shoulder Eye Bolts: Designed for lifting with an angular load.

- Long Shank Eye Bolts: Used for deeper engagement in lifting applications.

- **DIN 580, SASO 2101: Standards ensuring reliability and safety.

Brands Available:

Crosby, Lift-All, Harrington, Peerless, and Kito offer reliable and durable eye bolts and nuts.

General Maintenance:

Inspect eye bolts for wear, corrosion, or deformation. Ensure that threads are intact and that the bolt is securely fastened before use. Lubricate nuts and bolts to prevent corrosion and ensure smooth operation. Store in a dry, clean place when not in use.