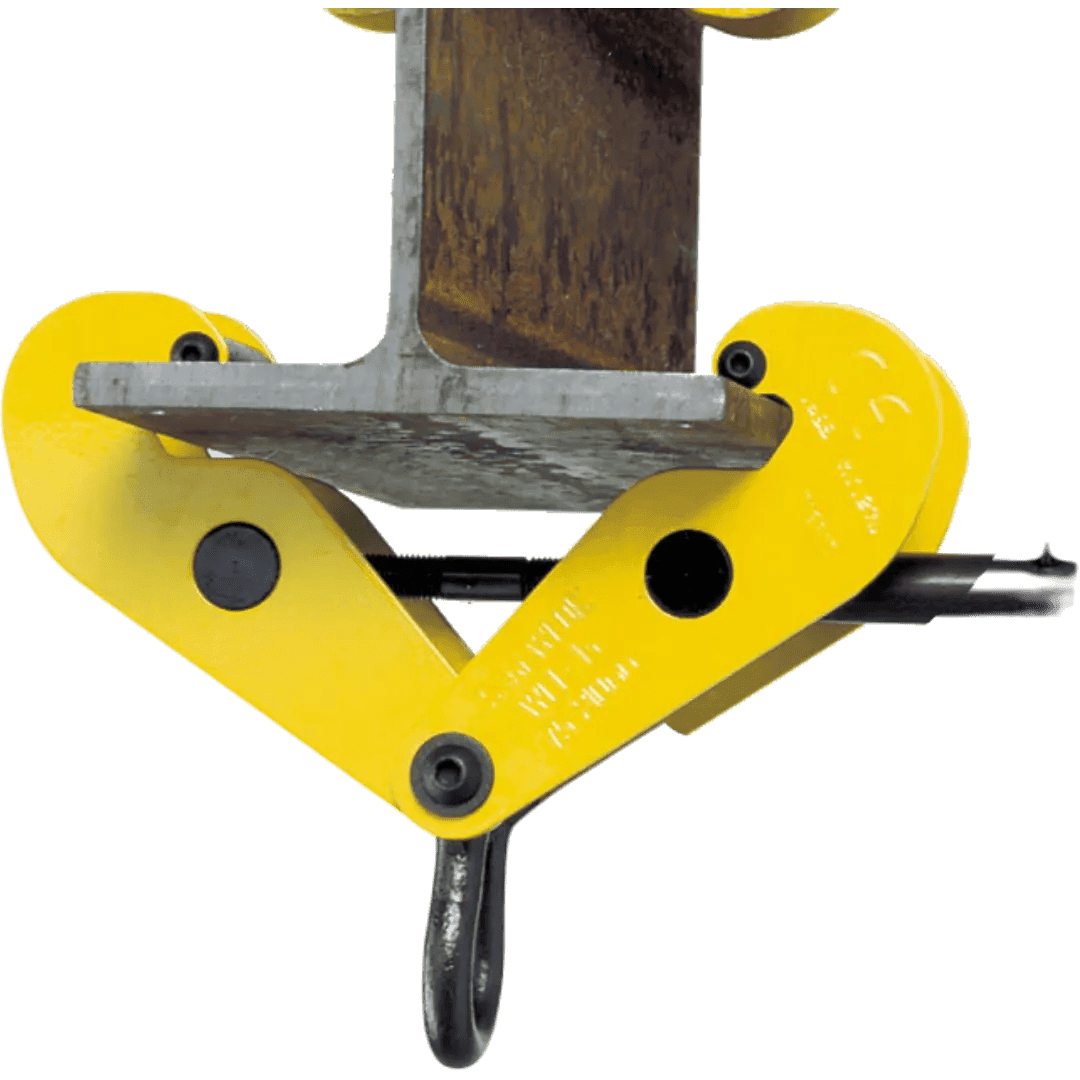

Beam clamps are rigging devices used to attach lifting equipment to a structural beam or other overhead structures, providing a secure lifting point. They are often used in construction, industrial, and rigging applications where overhead support is required. Beam clamps are typically made of high-strength steel and can be adjusted to fit different beam sizes. They are designed to be simple to install and remove, making them an excellent choice for temporary or mobile lifting applications. These clamps meet safety standards such as ASME B30.20 and SASO 1300 to ensure they are safe and reliable for use in critical lifting operations.

Key Features:

- Quick and Easy Installation: Can be installed without the need for welding or drilling.

- High Strength: Made from high-strength steel to handle heavy loads.

- Adjustable: Designed to fit various beam sizes and configurations.

- Portable: Ideal for temporary lifting applications.

Types and Standards:

- Standard Beam Clamps: For general-purpose lifting and rigging.

- Adjustable Beam Clamps: Can be adjusted to accommodate various beam sizes.

- **ASME B30.20, SASO 1300: Safety standards for beam clamps.

Brands Available:

Crosby, Kito, Harrington, and Lift-All offer high-quality beam clamps for secure lifting and rigging.

General Maintenance:

Inspect beam clamps for signs of wear, deformation, or damage. Ensure the adjustment mechanism is working correctly. Clean the clamp after use to prevent corrosion and lubricate moving parts. Store in a dry, secure area when not in use.