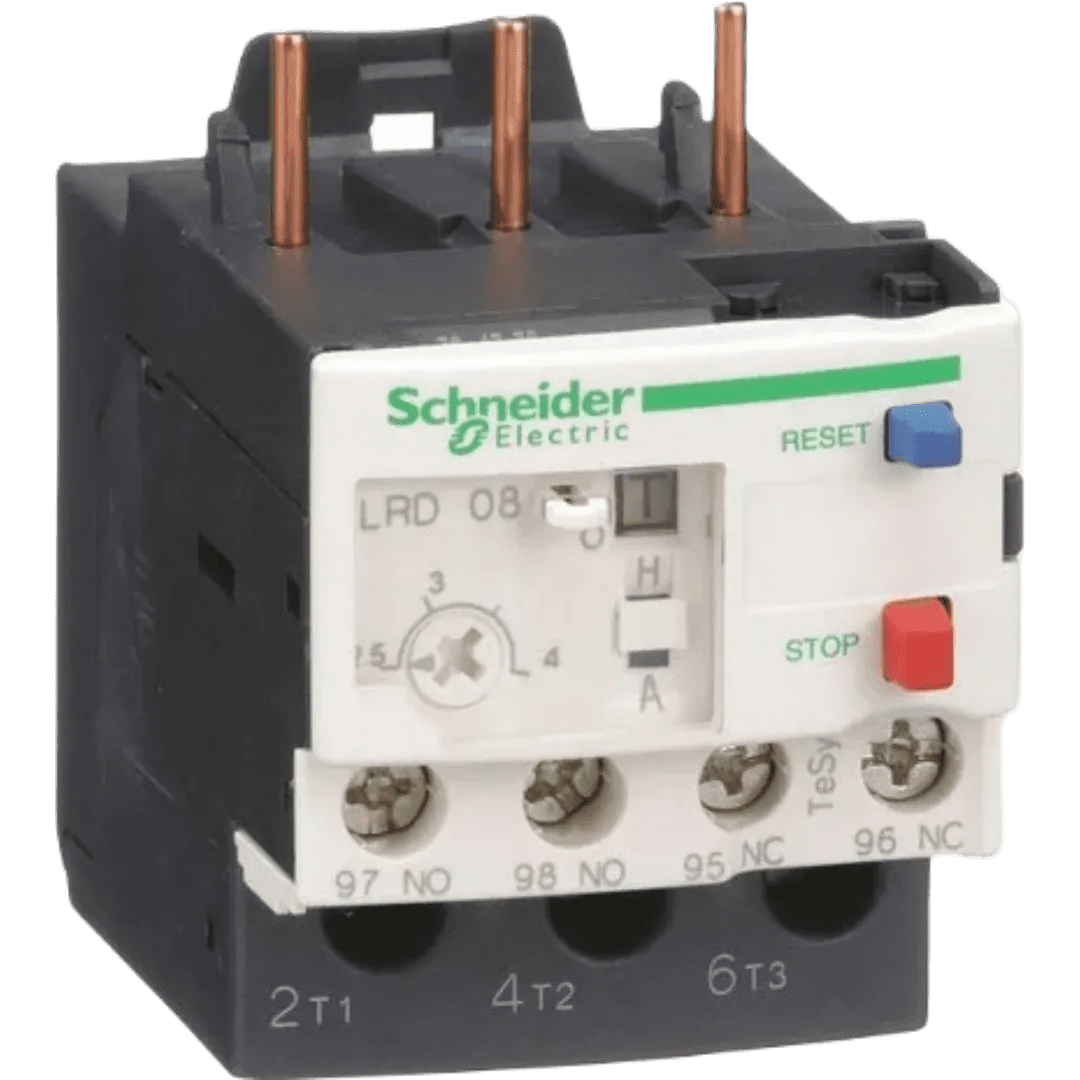

An overload relay (OLR) is an essential protection device designed to prevent motors and electrical equipment from damage due to excessive current. It works by detecting an overload condition and disconnecting the power before damage occurs. Overload relays are typically used in combination with motor contactors in industrial applications. These relays are available in both thermal and electronic types. Thermal overload relays use a bimetallic strip to detect temperature rise caused by excessive current, while electronic overload relays use sensors to provide more precise and adjustable protection. The relay resets automatically or manually once the overload condition is cleared.

Key Features:

- Motor Protection: Prevents motors from burning out due to excessive current.

- Adjustable Settings: Allows for customizable trip settings based on motor specifications.

- Types: Thermal and electronic overload relays, offering different sensitivity and precision.

- Cost-Effective: Extends the lifespan of motors and reduces the risk of costly damage.

Types and Standards:

- Thermal Overload Relays: Uses a bimetallic strip to trip on overheating.

- Electronic Overload Relays: Uses sensors for precise overload detection and reset features.

- **IEC 60947-4-1, ISO 9001: Common standards for overload relay construction and performance.

Brands Available:

Schneider Electric, Siemens, Eaton, ABB, Rockwell Automation.

General Maintenance:

Regularly inspect for wear and ensure the overload relay is correctly set for the application. Check the reset function and adjust the settings according to motor specifications. Clean the relay contacts and replace faulty relays to ensure reliable motor protection.