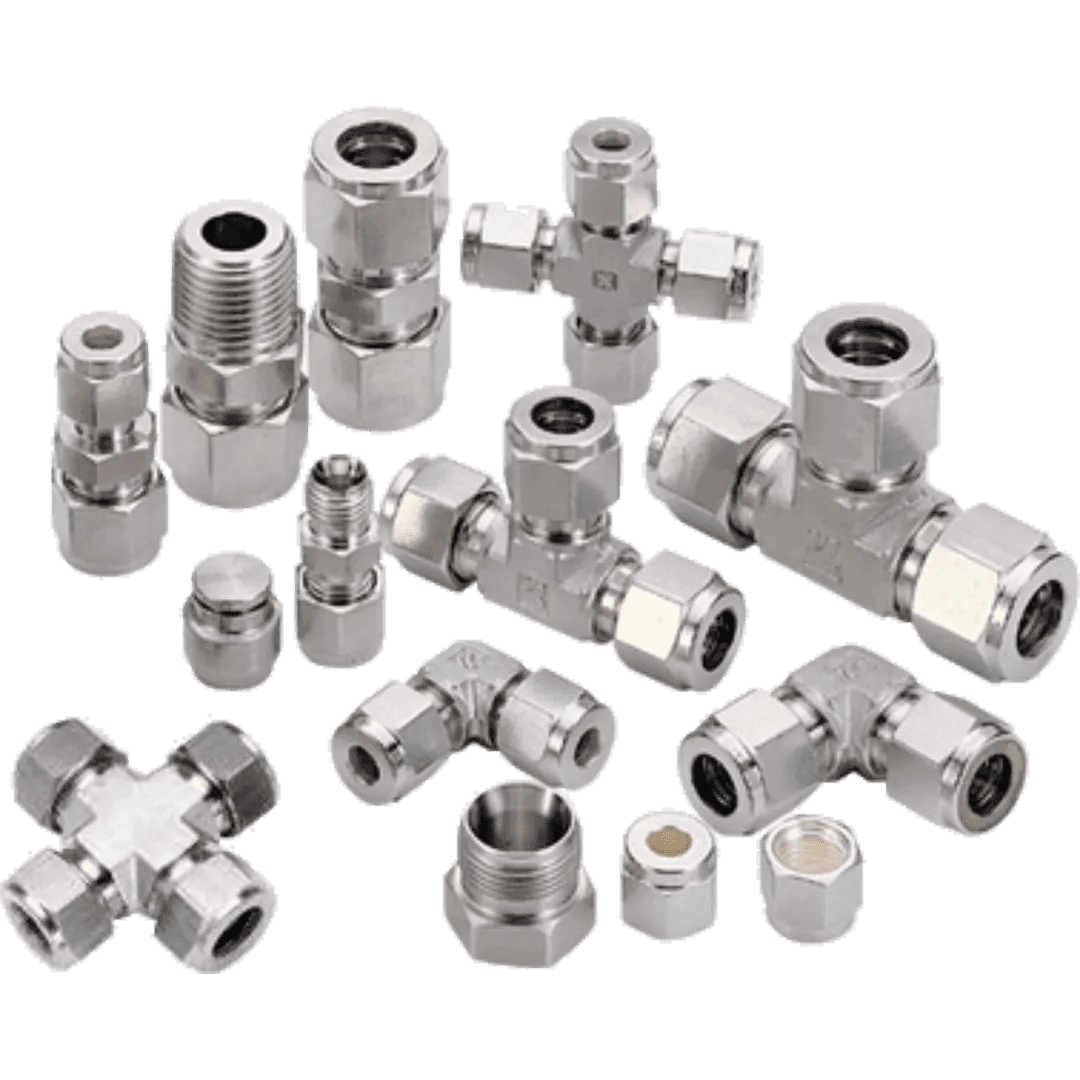

Stainless steel (SS) tubes and fittings are widely used in industries that require corrosion resistance, durability, and hygiene, such as food processing, pharmaceuticals, and oil & gas. These tubes and fittings are known for their strength, resistance to corrosion, and ability to withstand high temperatures and pressures. Stainless steel offers long service life and is easy to clean, which makes it ideal for sanitary applications. SS tubes are available in various grades, such as 304 and 316, depending on the specific environmental conditions and corrosion resistance required. SS fittings, including elbows, tees, unions, and adapters, ensure secure and leak-proof connections in pipe systems. Regular inspection for corrosion, especially in high-humidity environments, and cleaning are essential for maintaining system integrity.

Key Features:

- Corrosion Resistance: Ideal for environments exposed to corrosive substances or high humidity.

- Durable Construction: Withstands high temperatures, pressure, and wear.

- Sanitary: Easy to clean, making it suitable for food and pharmaceutical industries.

- Versatile Fittings: Available in various configurations such as elbows, tees, and reducers.

Types and Standards:

- Grade 304 SS: General-purpose stainless steel, resistant to corrosion and oxidation.

- Grade 316 SS: Higher corrosion resistance, ideal for food and medical applications.

- **ISO 9001, ASME BPE: Standards for stainless steel tube and fitting quality and hygiene.

Brands Available:

Swagelok, Parker, SSP, Hy-Lok, Swagelok.

General Maintenance:

Inspect for any signs of corrosion or leaks, especially at welded joints. Regularly clean tubes and fittings to avoid bacterial build-up, especially in sanitary environments. Tighten fittings to ensure secure connections.