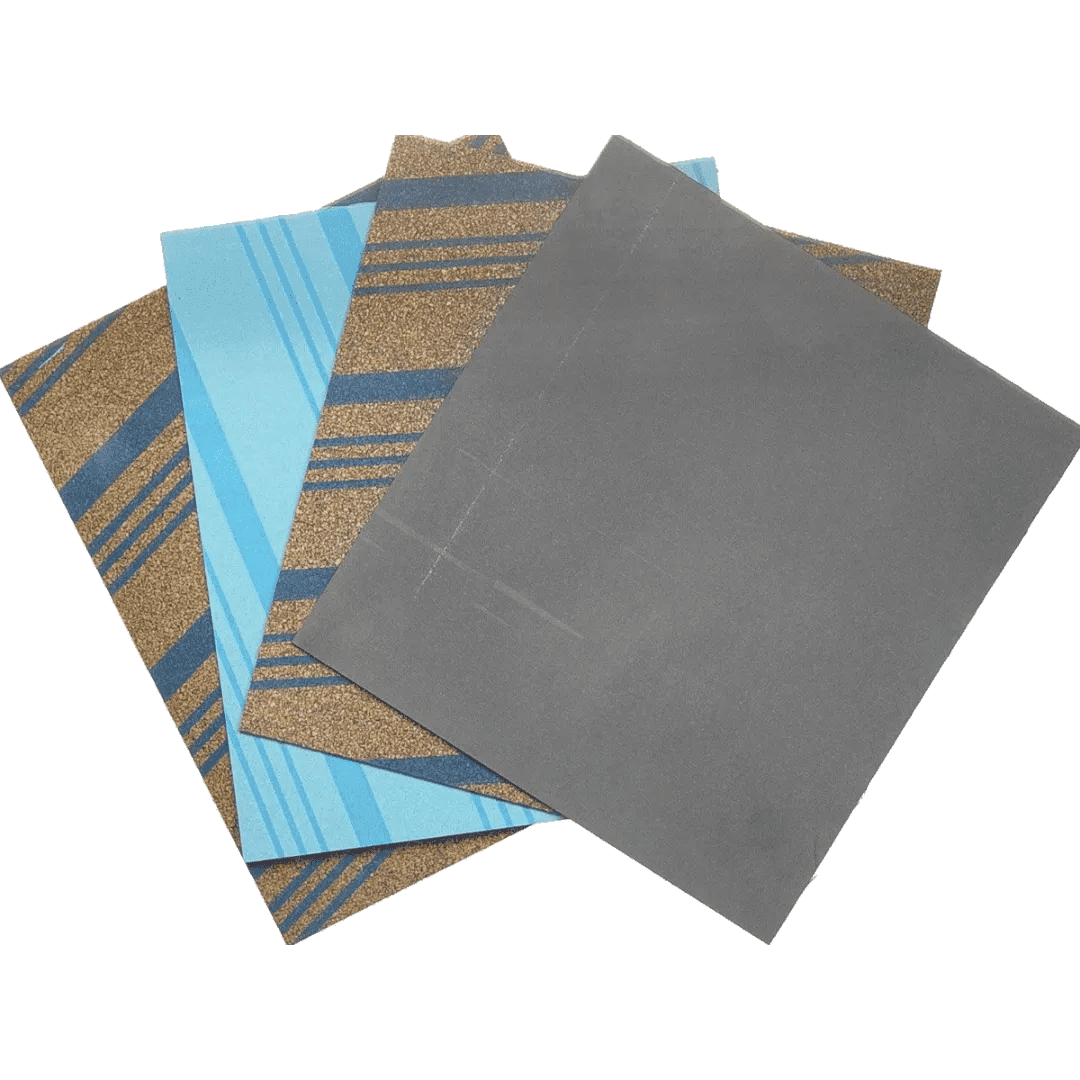

Gasket sheets are materials designed to create a seal between two mating surfaces, preventing the leakage of gases, liquids, or other substances. They are typically used in flanged joints in pipes, valves, pumps, and machinery. Gasket sheets are made from a variety of materials, such as rubber, PTFE (Polytetrafluoroethylene), graphite, and metal, depending on the application’s pressure, temperature, and chemical resistance requirements. For example, PTFE gaskets are ideal for high chemical resistance, while graphite gaskets are used in high-temperature applications. Gasket sheets come in different thicknesses and sizes and can be easily cut or punched to fit specific applications. Regular inspection for wear, corrosion, or material degradation is essential to maintain sealing performance.

Key Features:

- Leak Prevention: Creates a tight seal to prevent leaks between surfaces.

- Versatile Material Choices: Available in materials like rubber, PTFE, graphite, and metal.

- Wide Range of Applications: Used in petrochemical, automotive, HVAC, and food processing industries.

- High Temperature and Pressure Resistance: Suitable for harsh industrial environments.

Types and Standards:

- Rubber Gaskets: For general-purpose sealing in lower temperature applications.

- PTFE Gaskets: For chemical resistance in aggressive environments.

- Graphite Gaskets: Suitable for high-temperature and high-pressure applications.

- **ISO 9001: Standard for quality manufacturing of gasket materials.

Brands Available:

Garlock, Flexitallic, Klinger, James Walker, GORE.

General Maintenance:

Inspect gaskets for wear, cracks, or chemical degradation. Regularly clean mating surfaces before reinstallation. Replace gaskets that show signs of damage or loss of elasticity.