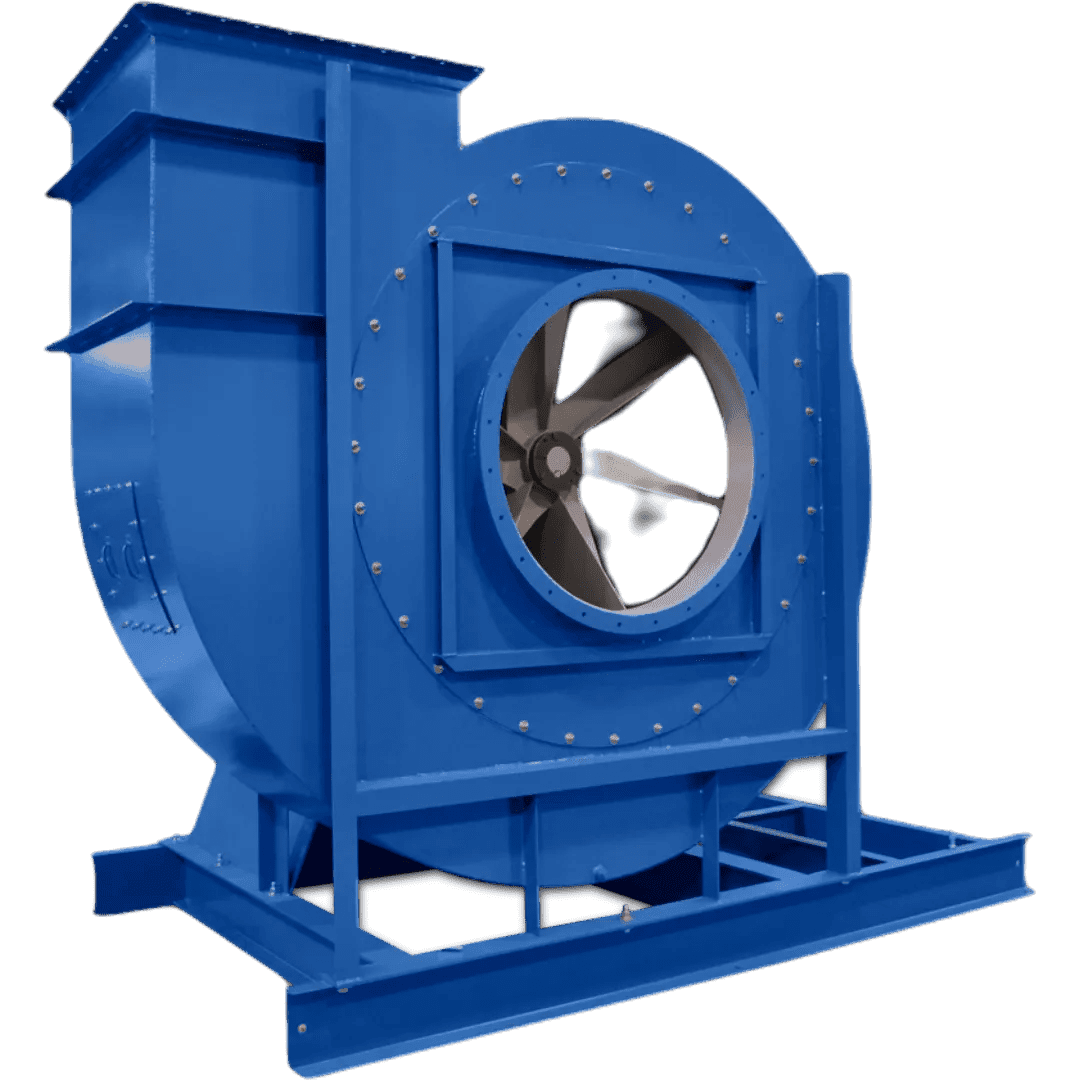

Industrial blowers are essential equipment in numerous industries, used to move air or gases in systems requiring ventilation, cooling, or exhaust. These blowers come in various designs such as centrifugal, axial, and mixed-flow types, each optimized for different airflow needs. Centrifugal blowers are ideal for high-pressure applications, while axial blowers are better suited for high-flow, low-pressure tasks. Regular maintenance, such as cleaning the fan blades, checking motor bearings, and inspecting belts, is necessary to ensure long-term performance. Spare parts like impellers, belts, and bearings are readily available for maintenance and repairs.

Key Features:

- High Airflow Capacity: Efficiently moves air or gases for ventilation, cooling, or exhaust.

- Variety of Designs: Includes centrifugal, axial, and mixed-flow blowers.

- Durable Construction: Built to withstand industrial environments with tough materials.

- Versatile Applications: Used in HVAC, mining, manufacturing, and agriculture.

Types and Standards:

- Centrifugal Blowers: High-pressure, low-flow applications.

- Axial Flow Blowers: High-flow, low-pressure applications.

- Mixed-Flow Blowers: Combination of both axial and centrifugal characteristics.

- ISO 9001*: Standard for product quality and performance.

Brands Available:

Howden, Greenheck, Chicago Blower, Twin City Fan, Fantech.

General Maintenance:

Lubricate bearings and check for signs of wear. Inspect fan blades for damage and debris buildup. Monitor motor health and ensure airflow efficiency by cleaning filters and ducts.