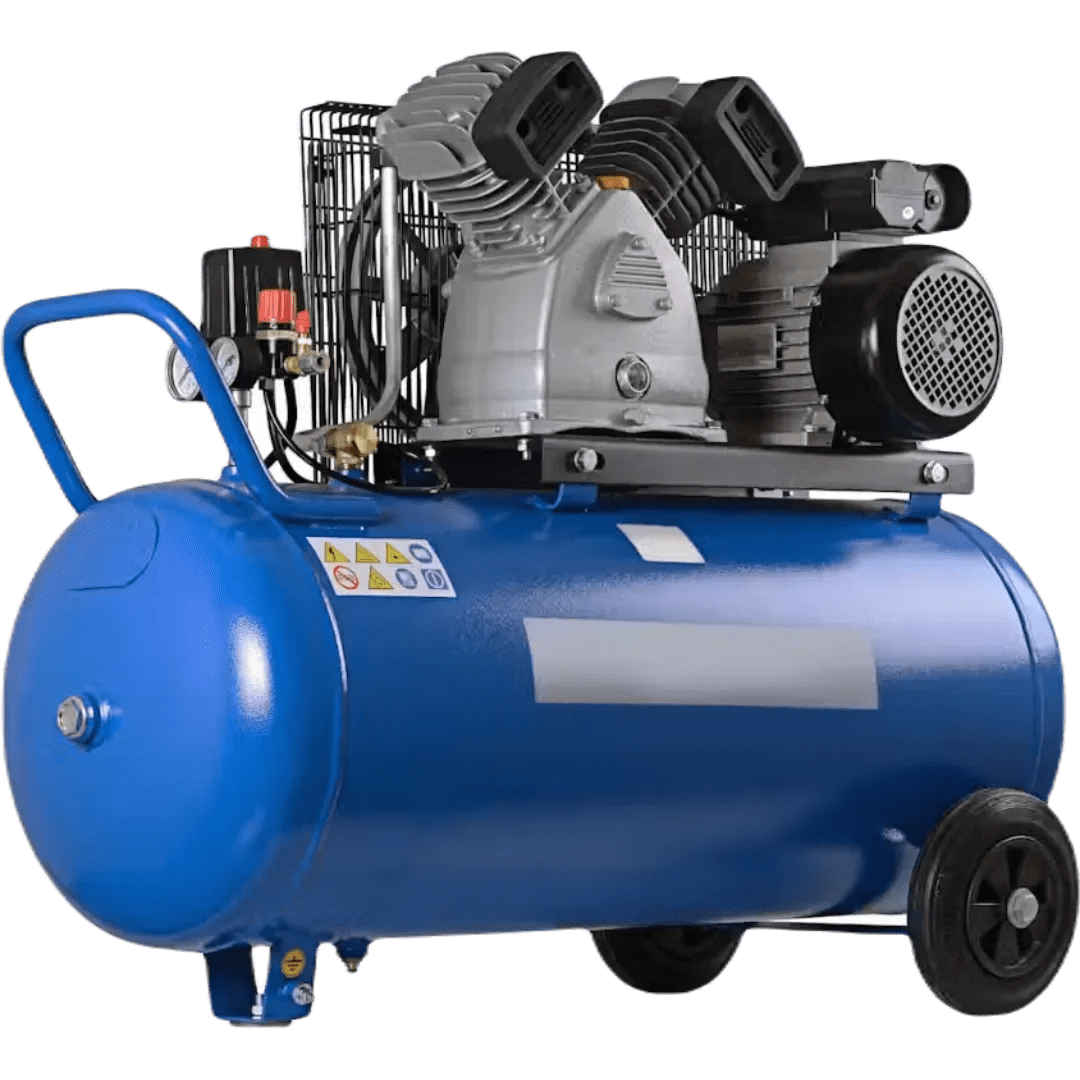

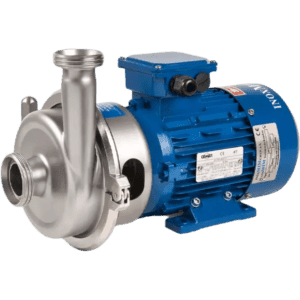

Compressors are machines that increase the pressure of air or gas by reducing its volume. These devices are crucial in a variety of industries, from automotive to manufacturing, for powering tools, machinery, and equipment. Compressors come in various types, including reciprocating, rotary screw, and centrifugal, each with specific applications depending on the required pressure and airflow. Spare parts for compressors are equally vital in ensuring the smooth operation and long lifespan of compressors, with common replacements including filters, valves, gaskets, and piston rings. Maintaining the efficiency of compressors is critical in industries such as construction, oil & gas, and manufacturing.

Key Features:

- Efficient Compression: Suitable for a variety of applications including power generation, automotive, and industrial processes.

- Variety of Models: Includes reciprocating, rotary screw, and centrifugal compressors.

- Comprehensive Spare Parts: Filters, gaskets, valves, seals, and other components.

- Energy Efficiency: Designed to reduce energy consumption while maximizing output.

Types and Standards:

- Reciprocating Compressors: Used for higher pressure applications.

- Rotary Screw Compressors: Best for continuous operation with minimal downtime.

- Centrifugal Compressors: Ideal for high-capacity air compression needs.

- **ISO 9001, SASO 2345: Industry standards for quality.

Brands Available:

Atlas Copco, Ingersoll Rand, Kaeser, Gardner Denver, Sullair.

General Maintenance:

Regularly check oil levels and replace filters. Inspect air intakes and clean exhaust ports. Follow the manufacturer’s recommended service intervals to avoid wear on internal parts.