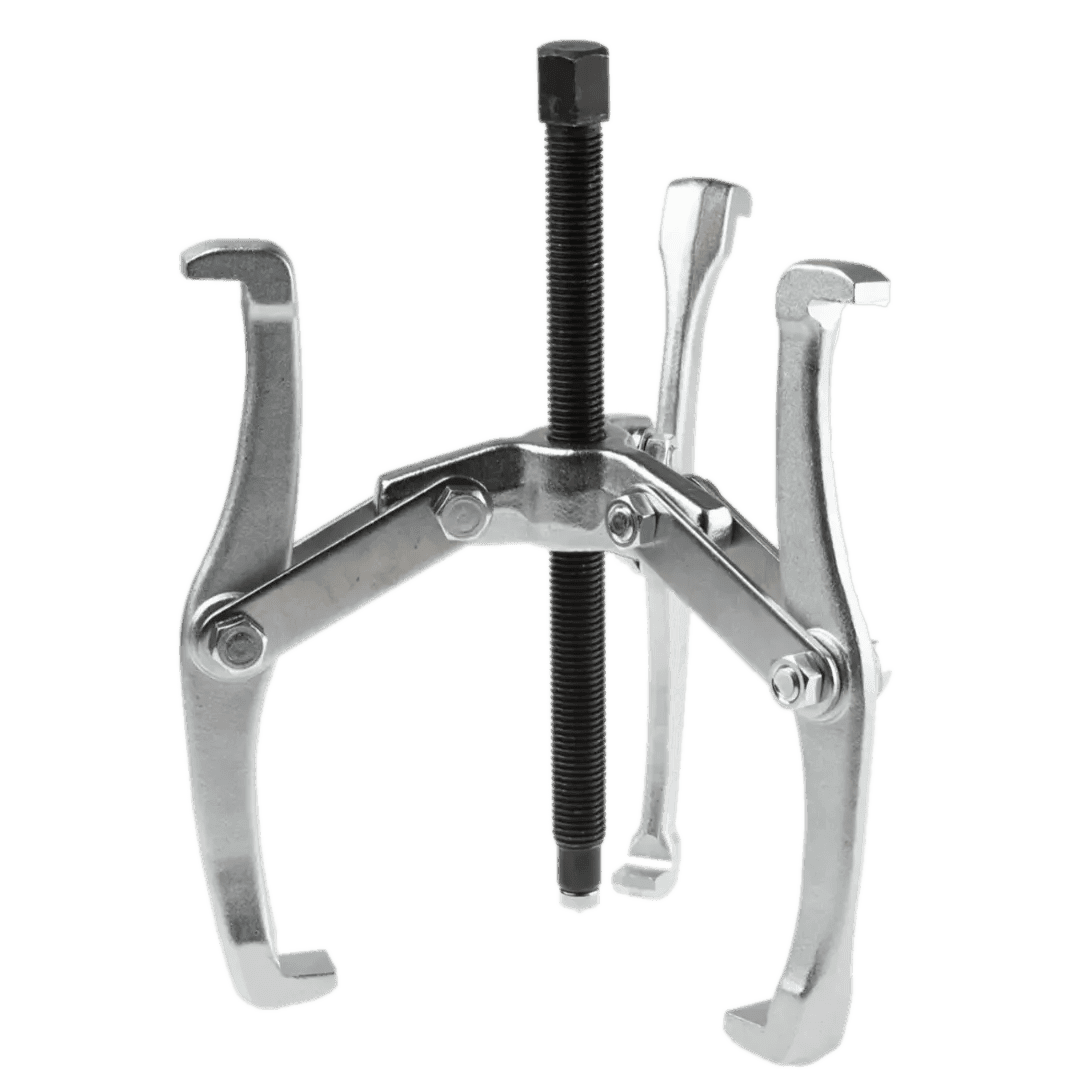

Bearing pullers are tools used to remove bearings from shafts, motors, or other machinery components without causing damage. These tools are designed to grip the bearing from the inside or outside, depending on the configuration, and provide a controlled way to pull it off the shaft. Bearing pullers are made from high-quality steel for durability and are available in different sizes and configurations, including two- and three-jaw designs. Bearing pullers meet industry standards such as ISO 6789 and SASO 2350 to ensure they can handle the high forces involved in bearing removal while maintaining safety.

Key Features:

- Easy Bearing Removal: Provides a controlled way to remove bearings without damaging components.

- Durable Construction: Made from hardened steel to withstand the forces required.

- Versatile Use: Available in multiple sizes and designs for different applications.

- Precision: Ensures accurate and smooth operation.

Types and Standards:

- Two-Jaw Puller: Ideal for smaller bearings.

- Three-Jaw Puller: Provides more stability for larger bearings.

- **ISO 6789, SASO 2350: Safety standards to ensure reliability and durability.

Brands Available:

SKF, Crosby, Hazet, KUKKO, and Park Tool offer high-quality bearing pullers.

General Maintenance:

Regularly inspect for any wear or damage to the jaws or threads. Lubricate the moving parts to reduce friction and prevent rust. Store the tool in a dry, secure location to prolong its lifespan.