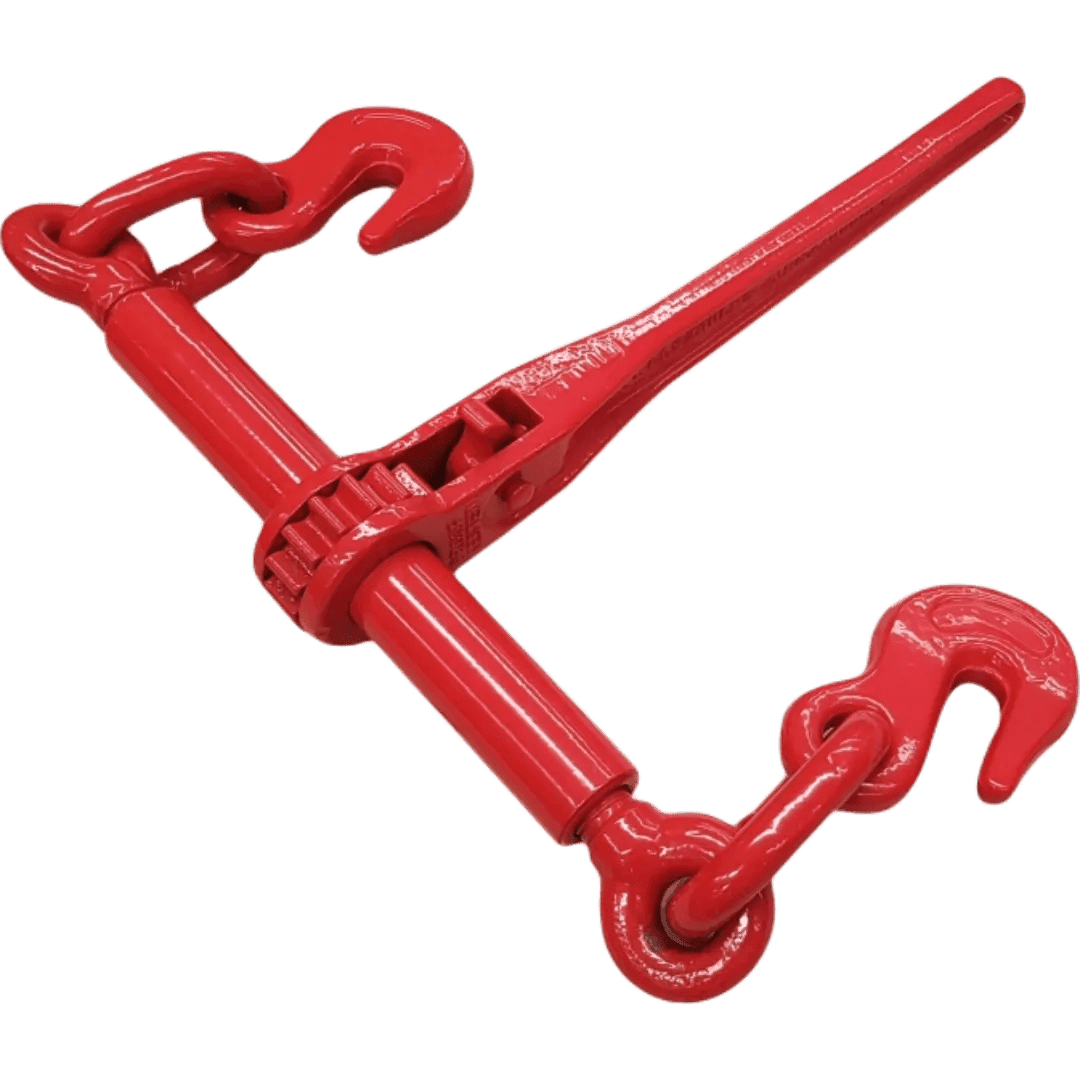

Ratchet type load binders are mechanical devices used to tighten chains or webbing around loads, ensuring they remain secure during transport. By using a ratcheting mechanism, they provide excellent tension and locking force, making them ideal for securing heavy loads on flatbeds, trailers, or other transport vehicles. These binders are made from high-strength steel and feature a ratchet handle that allows the operator to apply significant tension, reducing the risk of cargo shifting during transit. They are designed to meet rigorous standards like ASME B30.9 and SASO 2300, ensuring they provide safe and reliable load securing capabilities.

Key Features:

- Efficient Load Securing: Uses a ratchet mechanism to apply strong tension to chains or straps.

- Durable Construction: Made from high-strength steel to withstand the demands of securing heavy loads.

- Easy to Operate: The ratchet mechanism allows for quick and easy tensioning.

- Corrosion Resistance: Available in galvanized or powder-coated finishes to resist corrosion.

Types and Standards:

- Manual Ratchet Binders: Operated by hand for ease of use.

- Heavy-Duty Ratchet Binders: Designed for larger loads and more demanding applications.

- **ASME B30.9, SASO 2300: Safety standards ensuring the binder’s strength and reliability.

Brands Available:

Crosby, Peerless, Harrington, and Lift-All offer high-quality ratchet type load binders for various load securing applications.

General Maintenance:

Inspect the binder for any cracks, wear, or rust. Ensure the ratchet mechanism is functioning smoothly. Lubricate the moving parts to prevent rusting and keep the binder in good working condition. Store in a dry place to prevent corrosion.