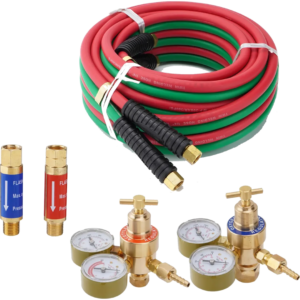

Flashback arrestors are essential safety devices used in oxy-fuel systems to prevent the dangerous backflow of gases, which can cause flashbacks (a reverse flow of gases back into the regulator or hoses). These devices are installed between the regulator and the hose to stop the flame from traveling back into the equipment. Flashback arrestors work by using a series of check valves and flame arresting filters to safely stop flashbacks, ensuring the safety of the welder and preventing potential equipment damage or explosions. Flashback arrestors must meet safety standards like ISO 5175 and SASO 2003 to ensure reliable and safe performance.

Key Features:

- Prevents Flashbacks: Protects equipment and personnel by preventing the reverse flow of gases.

- Built-in Check Valves: Automatically blocks any reverse gas flow to stop flashbacks.

- Durable Construction: Made from heat-resistant materials to withstand high-pressure and high-temperature conditions.

- Compact Design: Designed to be easily integrated into welding and cutting setups without taking up excessive space.

Types and Standards:

- Single-Stage Flashback Arrestors: Commonly used in light-duty and portable setups.

- Multi-Stage Flashback Arrestors: Provide added protection for heavy-duty applications, where the risk of flashbacks is higher.

- **ISO 5175, SASO 2003: Standards ensuring flashback arrestors meet safety requirements in welding and cutting operations.

Brands Available:

Harris, Victor, ESAB, Miller, and Lincoln Electric offer reliable flashback arrestors designed to meet industry standards and provide optimal safety.

General Maintenance:

Inspect the flashback arrestor regularly to ensure that it is free from dirt, debris, or contamination. Check the filters and valves for proper operation. Replace any worn or damaged parts, such as seals or gaskets. Ensure the arrestor is properly installed and secured in the gas line to prevent leaks. Store the device in a dry, clean area to prolong its lifespan.