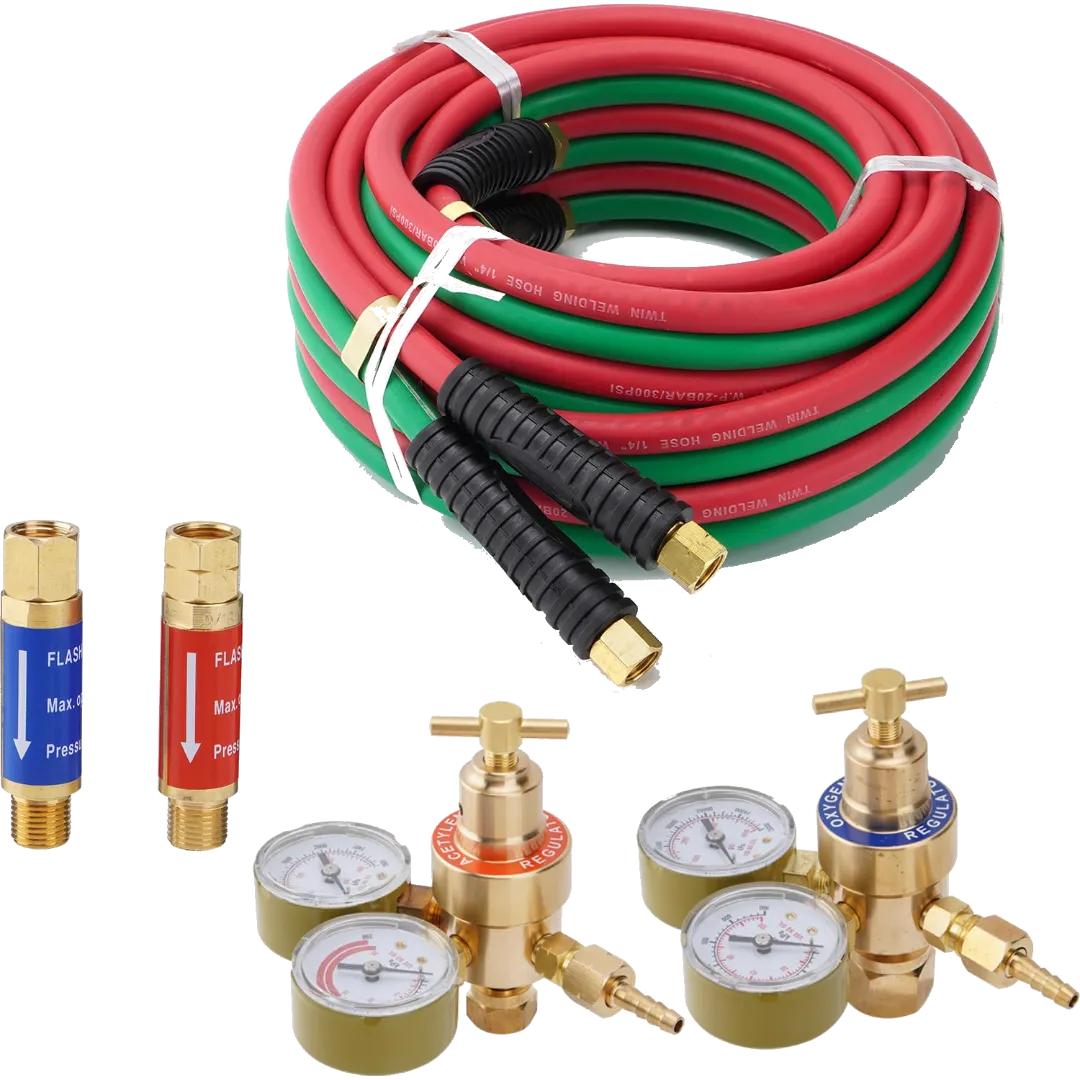

Oxygen-acetylene regulators and hoses are essential components of the oxy-fuel welding and cutting system. The regulator controls the flow of oxygen and acetylene gases to the torch, ensuring the correct gas pressure is maintained throughout the process. Oxygen and acetylene gases are delivered through durable, flexible hoses, which connect the regulator to the welding or cutting equipment. High-quality regulators ensure accurate pressure control, while hoses must be resistant to high temperatures and potential leaks. These products must meet international safety standards such as ISO 2503 and SASO 2201 to ensure reliable and safe operation.

Key Features:

- Precision Pressure Control: Regulates oxygen and acetylene flow for safe and effective welding and cutting.

- High-Temperature Resistance: Hoses are designed to withstand high pressures and temperatures without degradation.

- Easy Adjustment: Regulator dials allow for fine adjustments to gas pressure.

- Durable Materials: Regulators and hoses are made from robust, heat-resistant materials for longevity.

Types and Standards:

- Single-Stage Regulators: Typically used for light-duty applications and small jobs.

- Two-Stage Regulators: Provide more consistent pressure, ideal for heavy-duty or industrial applications.

- Flexible Hoses: Available in various lengths and diameters to suit different equipment setups.

- **ISO 2503, SASO 2201: Regulatory standards for pressure regulators and hoses in welding and cutting applications.

Brands Available:

Victor, Harris, Miller, Lincoln Electric, and ESAB are leading manufacturers offering high-quality oxygen-acetylene regulators and hoses for reliable performance in welding and cutting.

General Maintenance:

Regularly inspect hoses for leaks, cracks, or wear. Check the regulators for any signs of damage or irregular pressure readings. Clean the regulators to remove dirt or debris that may obstruct gas flow. Ensure that all hose connections are securely tightened, and replace hoses or regulators that show signs of damage or wear. Store the equipment in a dry area, away from direct sunlight and extreme temperatures.