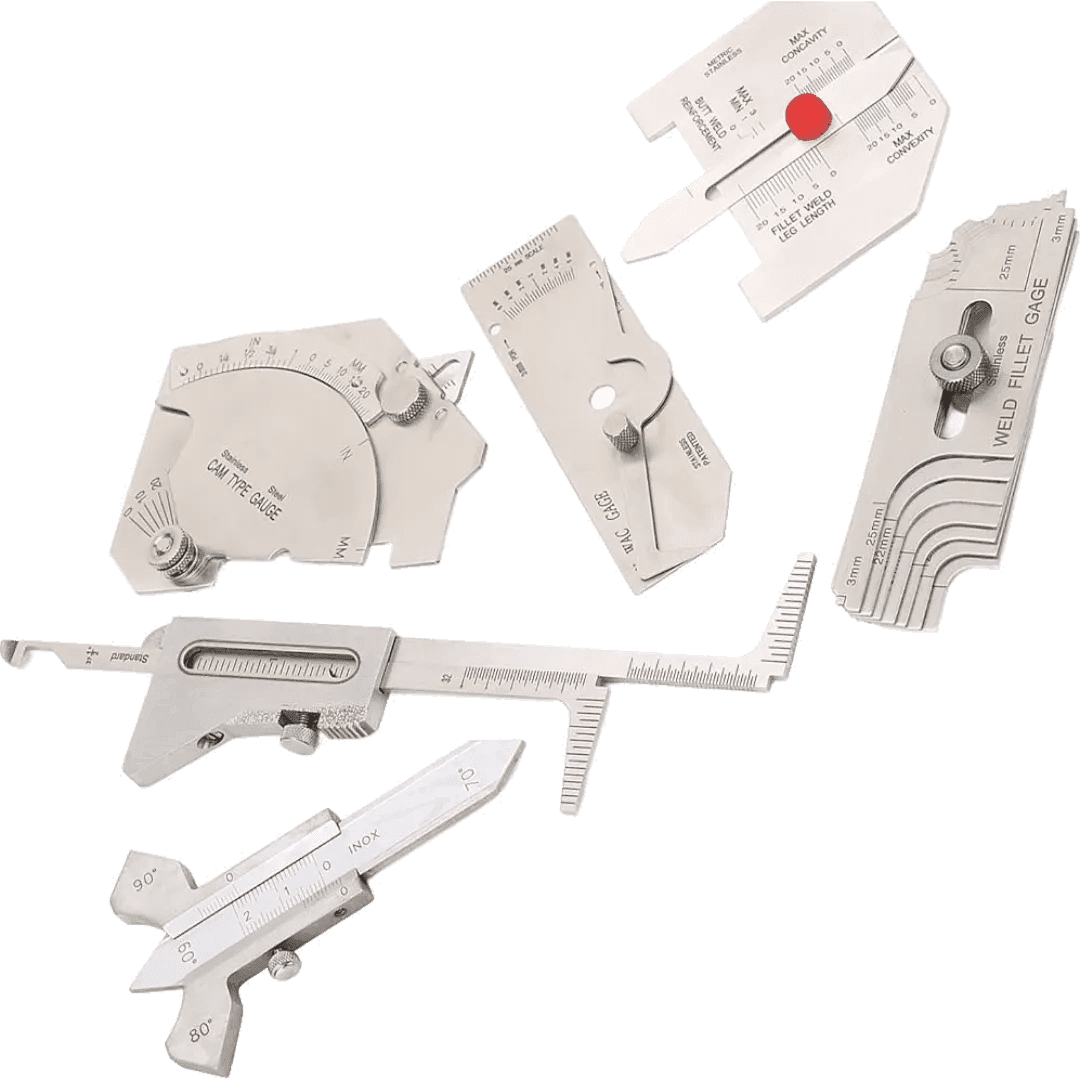

Welding gauges are essential tools for ensuring the quality and accuracy of welds. They are used to measure key parameters such as the throat depth, leg length, and bead size of a weld. Welding gauges help inspectors and welders maintain consistent quality control by ensuring that the welds meet the required specifications and standards. These tools are typically made from durable materials like stainless steel and are calibrated to meet international standards such as ASTM, AWS, and SASO 2201. Common types of welding gauges include fillet weld gauges, bevel gauges, and pipe weld gauges, each designed for specific welding applications. Welding gauges are indispensable for both visual inspections and precise measurements in the welding industry.

Key Features:

- Accurate Measurements: Helps ensure that welds meet specific design requirements and quality standards.

- Versatile Designs: Includes gauges for fillet welds, pipe welds, and other types of welds.

- Durable Construction: Typically made from stainless steel for longevity and resistance to wear.

- Easy to Use: Clear markings and measurement scales make them easy to use for inspectors and welders.

Types and Standards:

- Fillet Weld Gauges: Used for measuring fillet welds and ensuring the leg length and throat size are within specifications.

- Bevel Gauges: Designed to check the angle and alignment of welded edges.

- Pipe Weld Gauges: Used for checking pipe welds, especially in pressure vessels and pipe installations.

- **ASTM, AWS, SASO 2201: Standards ensuring the accuracy and quality of welding gauges.

Brands Available:

ESAB, Vulcan, Klein Tools, Weller, and Starrett are trusted brands offering a range of welding gauges for various types of weld inspections.

General Maintenance:

Welding gauges should be kept clean and free of debris or welding spatter. Store them in a protective case to prevent bending or damage. Regularly check the gauges for calibration to ensure they provide accurate measurements. Clean with a soft cloth and lubricate the moving parts if necessary.