Welding rods, also known as welding electrodes, are used as filler material to help join metals together during the welding process. They are essential for Stick welding and are available in a variety of materials, coatings, and sizes to suit different types of welding applications. The type of welding rod chosen depends on the material being welded and the required strength of the joint. Common welding rods include E6010 and E7018, typically used for mild steel, while stainless steel rods are used for TIG and MIG welding processes. Welding rods must meet industry standards such as AWS (American Welding Society) and SASO 2103 to ensure they are safe and effective for use in various welding conditions.

Key Features:

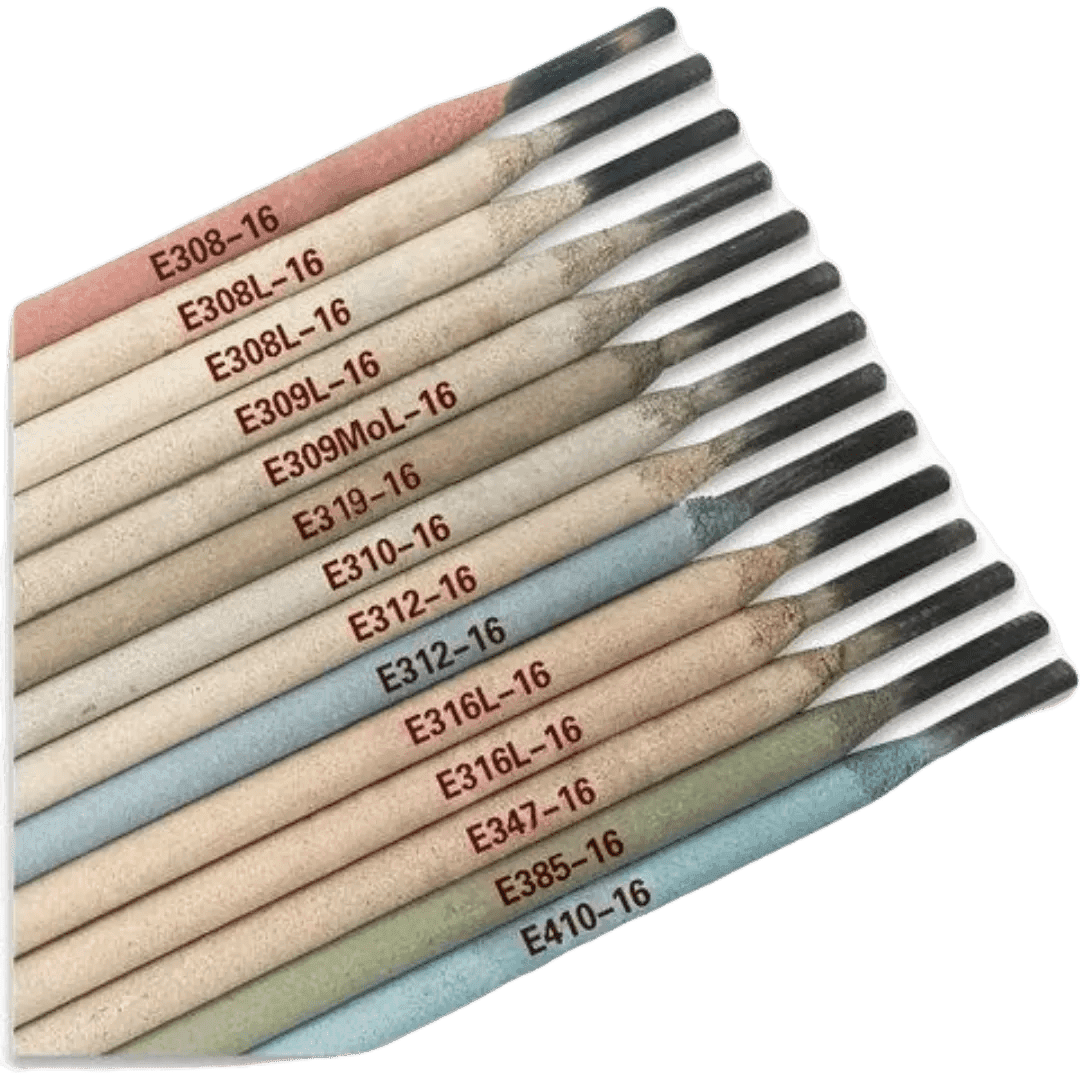

- Various Compositions: Includes rods for mild steel, stainless steel, aluminum, and other metals.

- Coating Types: Available in rutile, basic, and cellulosic coatings to provide different arc stability and slag removal characteristics.

- Diameter and Length Options: Available in various sizes for different types of welds and welding processes.

- Good Arc Stability: Ensures easy striking and stable arc during welding.

Types and Standards:

- Mild Steel Rods: For general-purpose welding of mild steel.

- Stainless Steel Rods: For welding stainless steel materials, providing resistance to corrosion.

- Aluminum Rods: Special rods used for welding aluminum and its alloys.

- **AWS, SASO 2103: Standards ensuring the quality and performance of welding rods.

Brands Available:

ESAB, Lincoln Electric, Harris, Forney, and Hobart are popular brands offering a variety of high-quality welding rods suitable for different welding applications.

General Maintenance:

Welding rods should be stored in a dry area to prevent moisture absorption, which can lead to welding defects. Ensure the rods are kept in their original packaging or in sealed containers. Inspect rods for any signs of corrosion or damage before use. Discard any rods that appear cracked or damaged to maintain high-quality welds.